A decanter centrifuge requires a drive system, which is normally divided into two parts. The whole rotor must operate at a high rotational speed so that the solids are pushed against the inside wall of the bowl due to the centrifugal force. In addition, the scroll must rotate inside the bowl at a low rotational speed difference (differential speed) relative to the bowl. The differential speed determines the retention time of the solids in the bowl. This has a significant influence on the separation process. The solids are conveyed in the direction of the narrow bowl output. This generates high levels of torque. The ROTODIFF scroll drive conveys the solid material automatically as a function of the available scroll torque. This results in continuous adaptation to the operating parameters in order to guarantee optimal output of solid material.

The scroll and bowl drives of the hydrostatic drive system operate independently from one another in terms of energy and control technology. The torque and differential speed can be controlled based on the load and proportionally to the system pressure. In all systems, the drive carries out direct and infinitely variable control automatically, which allows ongoing, optimal adaptation to the separating tasks.

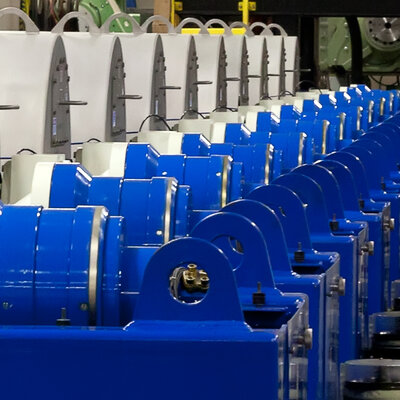

The ROTODIFF hydrostatic scroll drive is a radial roller piston motor capable of high torque, which is mounted directly on the bowl system, where the housing (stator) is flanged onto the bowl and the rotor directly drives the scroll. The hydrostatic transfer seal coupling enables operation of the scroll drive that covers the turned part.

The ROTODIFF with a constant displacement drives the scroll at the differential speed required for the separation process based on the load. This ensures a continuously optimal output.

Pump unit for scroll drive system (semi-hydraulic drive)

The pump unit supplies the oil to the ROTODIFF hydraulic motor which is directly attached to the bowl. The ROTODIFF rotor drives the scroll directly. The scroll drive system consists of the ROTODIFF hydraulic motor and a hydraulic pump unit as well as a control unit. The bowl drive with frequency-controlled electric motor is provided by the centrifuge manufacturer.

Pump unit for scroll and bowl drive system (fully hydraulic drive)

The pump unit consists of two independent hydraulic circuits for the scroll and bowl drives. The pump unit supplies the oil to the ROTODIFF hydraulic motor, which drives the scroll directly. In addition, the same pump unit also supplies the oil to the bowl drive, which is driven by a hydraulic motor. As such, the fully hydraulic drive system consists of the scroll drive with ROTODIFF and the bowl drive with hydraulic motor as well as the pump unit and a control unit.