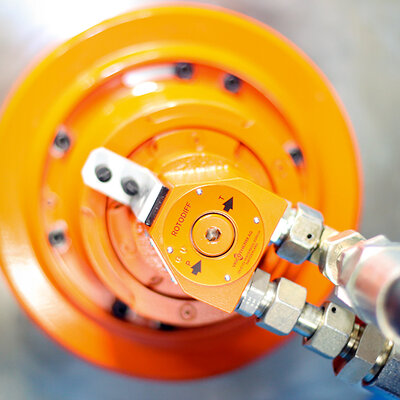

“Increased decanter power and improved separation results thanks to the hydrostatic ROTODIFF drive.”

For over 45 years, Viscotherm AG has continued to develop separation technology with ROTODIFF decanter centrifuge drives through continuous innovation. One of the main features is the optimal ease of adaptation to a wide variety of operating conditions.

Application examples: Waste water treatment plants / Chemical industry / Food industry / Drilling technology / Bio fuels / Environmental technology, mobile equipment / General industry

Industrial waste water, slurry, communal waste water, tannery sludge, slurry oil, bioethanol etc.

Treatment: Reclamation of drilling fluids, reclamation of barite, removal of water and conditioning of drilling mud, tunnelling etc.

Aluminium hydroxide, calcium carbonate, kaolin, coal mines, coal dust, titanium dioxide etc.

Alum sludge, iron oxide, dye pigments, gypsum, silica, mineral oil, polyethylene, PVC various salts, zinc chromate, bio substrates, insulin, intermediate pharmaceutical products

Beer yeast and wine lees, blood, fish meal, fish industry, meat extracts, fruit juices, gelatine, vegetable juices, grain mash, gluten, potato protein, potato peels, cheese production, casein, lactose, monosodium glutamate, plant extracts, vegetable oil, proteins, starch, animal fats, drinking water processing, wine yeast and wash, wheat starch etc.

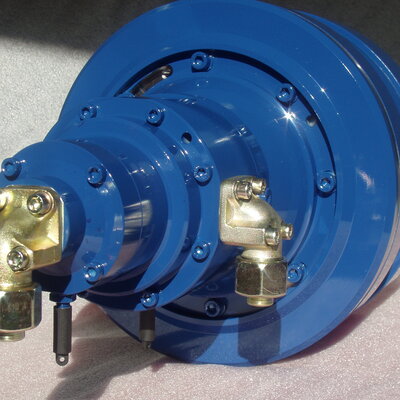

Hydraulic solid bowl – scroll centrifuge drives from Viscotherm offer significant advantages. This is particularly true of products that are difficult to process, such as meat-and-bone meal, fish meal, casein, lactose, starch, PVC, cellulose derivatives etc. These products have a tendency towards vibration or adhesion (chatter). The service life of a ROTODIFF drive is many times longer than that of a gear unit. This is fully applicable in potentially explosive atmospheres thanks to ATEX certification.

VISCOTHERM develops and produces hydraulic ROTODIFF drive systems for a wide variety of applications. The drive systems are designed based on the required torque (ROTODIFF) and required differential speed (pump unit).

New York City, Philadelphia, Seattle, Atlanta, Baltimore, Toronto, Seoul, Singapore, Kasai in Tokyo, Yokohama, Ho-Chi-Minh, Vienna, Amsterdam, Helsinki, Prague, Valencia, Berlin, Stammheim in Cologne, Munich, Frankfurt, Thames Water etc.

Ashland, Akzo Nobel, BASF, Bayer, Dow Chemical, Du Pont, Eastman, Lanxess, Novartis, Sandoz, Vinnolit, Shin Etsu etc.

ADM, Bayerische Milch Industrie, Del Monte, Dr. Oetker, Emmi, Gallo, IBP, Mondavi, Polskamp, Syral, Sunkist etc.

(Oil industry, tunnelling, mining)

AMC Baker & Hughes, Drexel, Halliburtion, Herrenknecht, Nov, Oiltools, PSD, SCS, Swaco, Task, Wayss & Freytag etc.

SASOL-South Africa, Somerset etc.

Huning, MSE, Petroleum Solids Control, Clean Harbors, Veolia etc.

Mercedes Raststatt, Nampak, OJ-Papers, Sappi etc.